TECHNOLOGY DESIGNER SPRING 2025

THE FORTRESS STORY

By Stephanie Casimiro

WHEN I SAT DOWN WITH GABI WOLPER, President of Fortress Seating, I expected to hear a straightforward history of a company that builds high-end home theater seating. They do in fact produce some of the most gorgeous cinema seating in the industry, but what I didn’t anticipate was a fascinating journey that eventually led to their becoming a leader in their field of expertise. What struck me most wasn’t just the company’s evolution but the deep commitment to craftsmanship, quality and customer satisfaction passed down through generations. As we spoke, it became clear that Fortress isn’t just about making chairs — it’s about creating long-lasting, tailor-made seating experiences that stand the test of time.

STEPHANIE: Tell me about the history of Fortress.

GABI: Fortress is an 80-plus-year-old company that started in the 1930s, originally manufacturing desks and filing cabinets. Based in Southern California, we pivoted during World War II to produce ammunition boxes due to our steel fabrication capabilities. In the 1950s, we expanded into office seating while continuing to create desks and files. Over time, seating became our primary focus.

A fun anecdote about our legacy: When I met my wife in 2005, she was working at a high school and noticed an old filing cabinet with the Fortress logo. She asked if it was one of ours, and sure enough, it was. It’s incredible how our products have endured for decades.

Even though we stopped producing desks and files after a factory fire in 1979, we still receive calls from customers looking for replacement keys. Occasionally, I come across old Fortress filing cabinets on eBay and buy them for nostalgia’s sake.

STEPHANIE: That’s a great story. Your company has made quite a transformation over the years. How did Fortress transition from manufacturing ammunition boxes and filing cabinets to high-end seating?

GABI: The transition was gradual. Our steel filing cabinets earned us the name Fortress because they were built to last. Over time, we moved into commercial seating — executive seating, reception seating, and conference room chairs. In the 1980s, we entered the healthcare industry, designing recliners for kidney dialysis and chemotherapy patients. These chairs had to be exceptionally durable and comfortable since they were used around the clock. That experience with recliners set the stage for our future in luxury seating.

Fortress has always been a family-run business, though we aren’t the original owners. My father joined the company in 1986 as a sales manager, having previously worked in the furniture industry with companies like Herman Miller. In 1991, he purchased Fortress from its founding family, and under his leadership, continued to have success in the commercial world, but saw an opportunity in residential markets and began expanding there.

STEPHANIE: How did Fortress move from healthcare seating to home theater seating?

GABI: That happened by chance. In the late 1990s, a local theater designer, Neil Parsons, reached out to my father. He was dissatisfied with the available theater seating options and asked if we could design a chair for home theaters. My father’s response was, “What’s a theater chair?” After hearing Parsons’ vision, we took on the challenge. Our first designs were quite rudimentary — we even placed cup holders on top of the armrests instead of recessing them. This initial project introduced us to the home theater industry and connected us with local system integration companies.

Word spread and a sales representative introduced us to additional technology design firms, helping us establish a foothold in the market. My father personally traveled across the country with his reps, demonstrating our seating to potential dealers. Eventually, in 2005, I joined the company to take on some responsibilities and have been here for 20 years.

STEPHANIE: That was right at the beginning of the home theater boom. It must have been an exciting time. How does Fortress maintain its high standards while adapting to industry trends?

GABI: We operate in the high-end market, catering to designers, architects and discerning clients who demand exceptional craftsmanship. Our philosophy is to be more meticulous than our clients — if a flaw is identified before a product leaves our factory, it’s not a mistake. Our factory team is empowered to spot and correct issues early in the process, ensuring the highest level of quality.

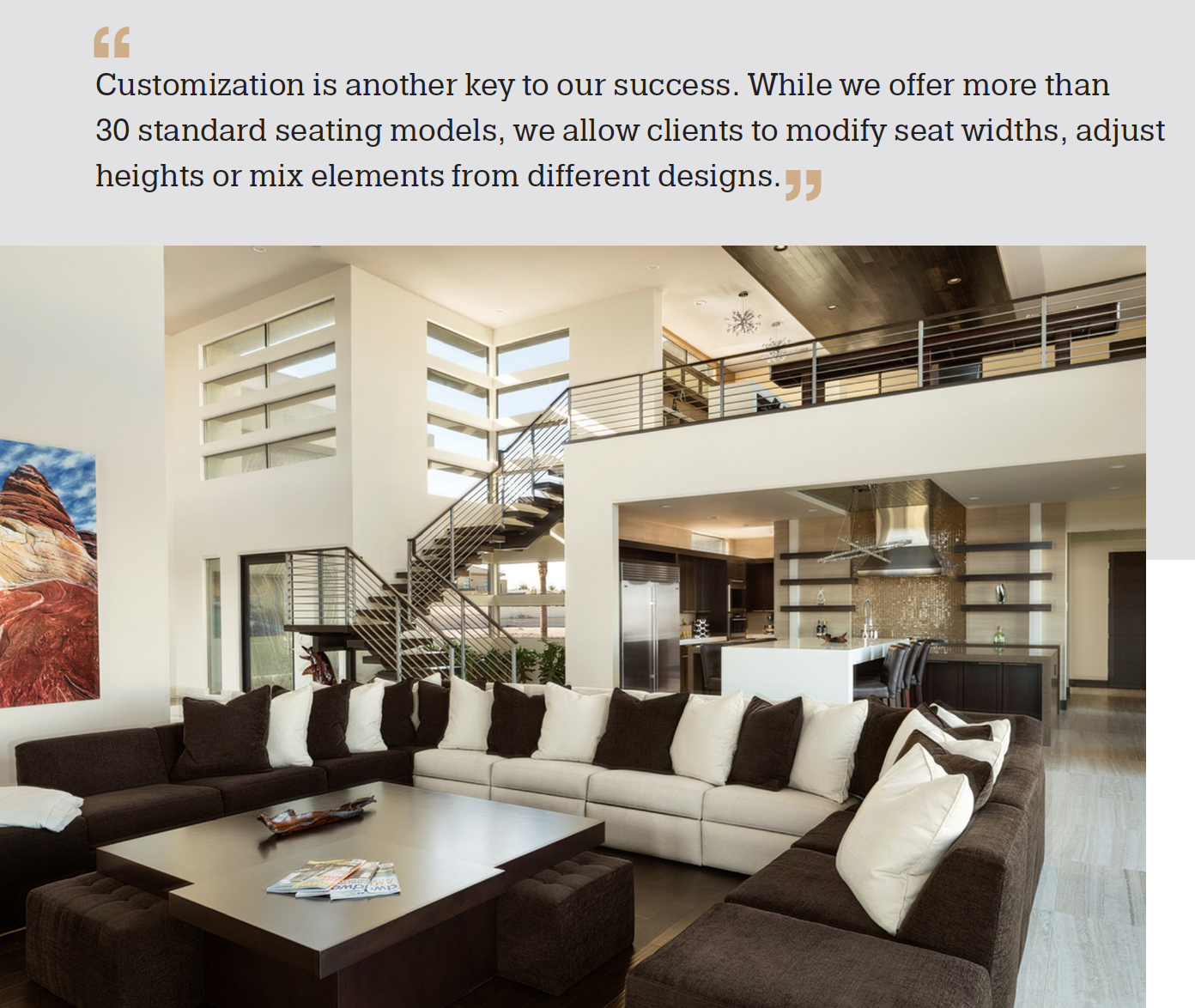

Customization is another key to our success. While we offer more than 30 standard seating models, we allow clients to modify seat widths, adjust heights or mix elements from different designs. Many competitors consider these requests custom work, but for us, it’s routine. Beyond that, we frequently develop fully custom pieces based on designer specifications or client needs.

STEPHANIE: Any particularly challenging custom projects come to mind?

GABI: Many of our high-profile projects are private, so we don’t always get to see the final installations. However, one of our current projects involves a home theater with intricate, curved walls and a seating layout that must fit together like a puzzle. The precision required is immense, but seeing such ambitious designs come to life is rewarding.

We’re also working on a project for a superyacht, where space constraints present unique challenges. The client wants recliners, but they need to be compact and seamlessly integrated into the yacht’s aesthetic. We’ll be prototyping the design soon, and the client’s team will visit our factory to approve it.

STEPHANIE: Fortress has a reputation for durability. Have you had clients return years later asking for the same seating?

GABI: Absolutely. One memorable example is from Williams-Sonoma, which also owns Pottery Barn. In the 1980s, we built seating for their boardroom. Twenty-five years later, they contacted us — not to shop around or request a new design, but to order the exact same seating. That level of brand loyalty is something we strive for.

STEPHANIE: Fortress competes in a niche market. What sets you apart from other seating manufacturers?

GABI: The biggest differentiator is that we are the actual manufacturer. We produce everything in-house here in the U.S., allowing us to maintain strict quality control. Many competitors outsource their manufacturing, which limits their ability to customize products. Because we build everything from scratch, it gives us a level of control and customization that really is unparalleled. If someone wants a very specific design, we can do that, or if they need the seating built to exact dimensions to fit their room or their client, we are happy to accommodate.

STEPHANIE: How do you incorporate evolving smart home trends into your seating?

GABI: We take our cues from system integrators and dealers who bring us client requests. USB charging ports and power integration are standard now. Years ago, we did a lot of touchscreen integrations, but today, clients prefer solutions that work with iPads or voice-controlled systems like Josh.ai. Some want fully automated seating that syncs with their home theater system — press a button, and the chair moves into the perfect viewing position.

We also developed motorized seat height adjustments for rooms where risers aren’t an option. The seats can elevate by up to eight inches to improve sightlines, offering a flexible solution for retrofitted spaces.

STEPHANIE: What trends are shaping the future of the home cinema industry?

GABI: We still see strong demand for dedicated theater recliners, but there’s a growing interest in more versatile furniture — sectionals, club chairs with ottomans, and lounge-style seating. Many clients want their home theater to blend with the rest of their living space rather than resemble a commercial cinema. This shift has opened opportunities for us to design furniture beyond theaters, including seating for living rooms, master bedrooms and even bar areas.

STEPHANIE: Fortress has thrived under your leadership for nearly two decades. What are you most proud of?

GABI: Seeing Fortress grow year after year while maintaining our reputation for quality and customer service has been incredibly fulfilling. Our employees are also a big part of our success — many have been with us for decades. One employee retired after 40 years but found retirement boring, so we invited him back on a part-time basis to mentor younger team members. That kind of dedication speaks volumes about our company culture.

STEPHANIE: That’s a rare and remarkable testament to Fortress. It’s been a pleasure speaking with you, and I look forward to sharing your story. Thank you, Gabi.

GABI: Thank you. I appreciate the opportunity.